Commercial Services

Your experienced partners for complex projects.

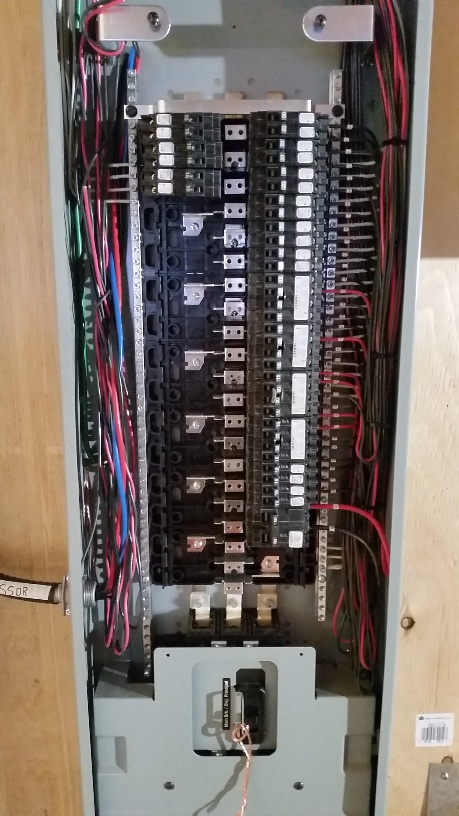

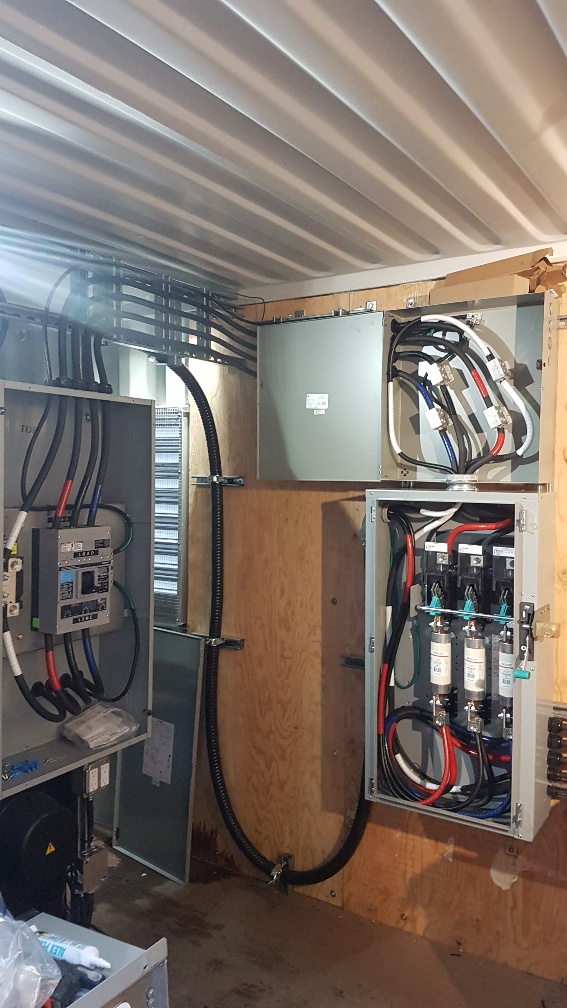

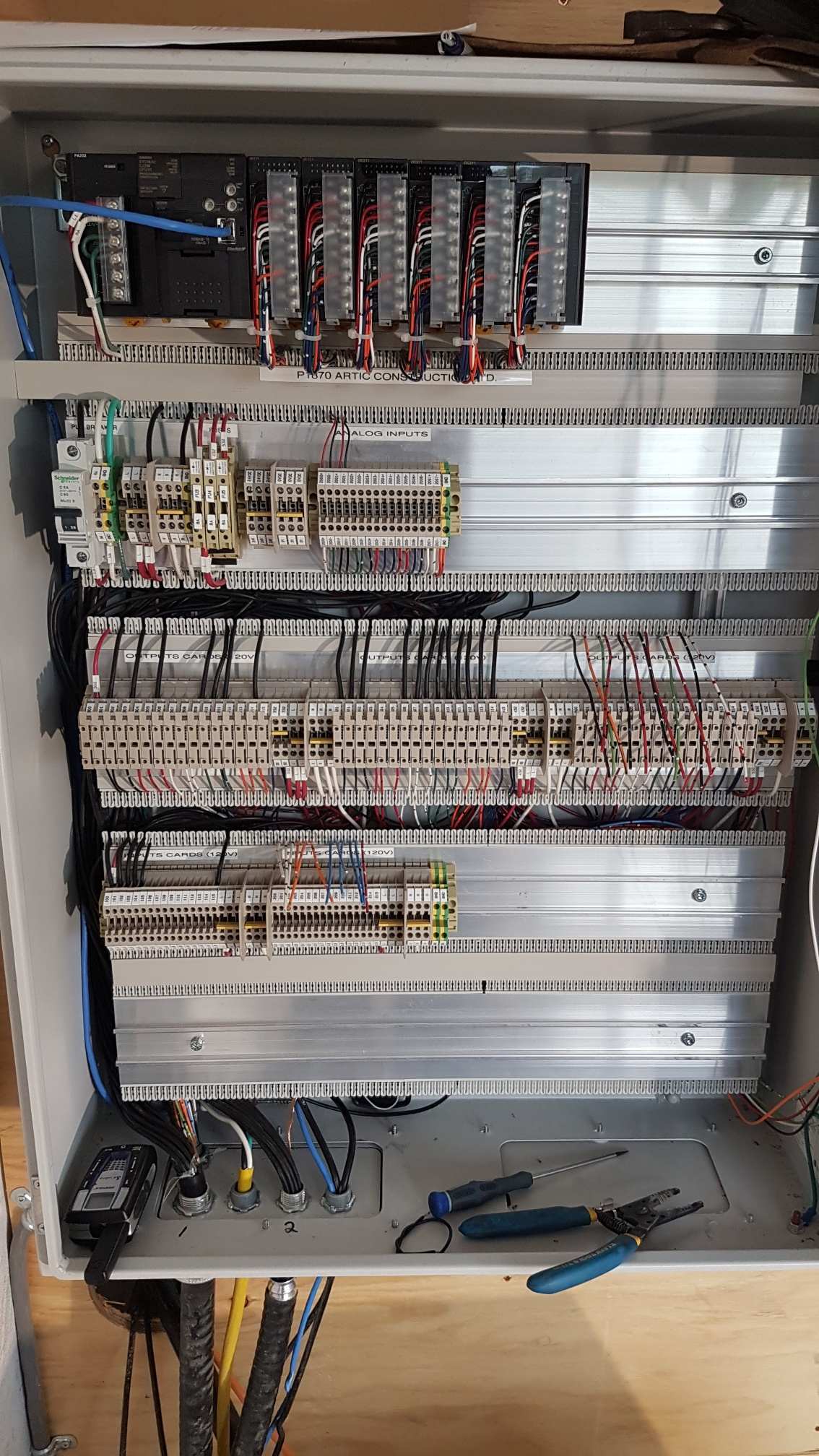

Commercial & Industrial

Learn More +

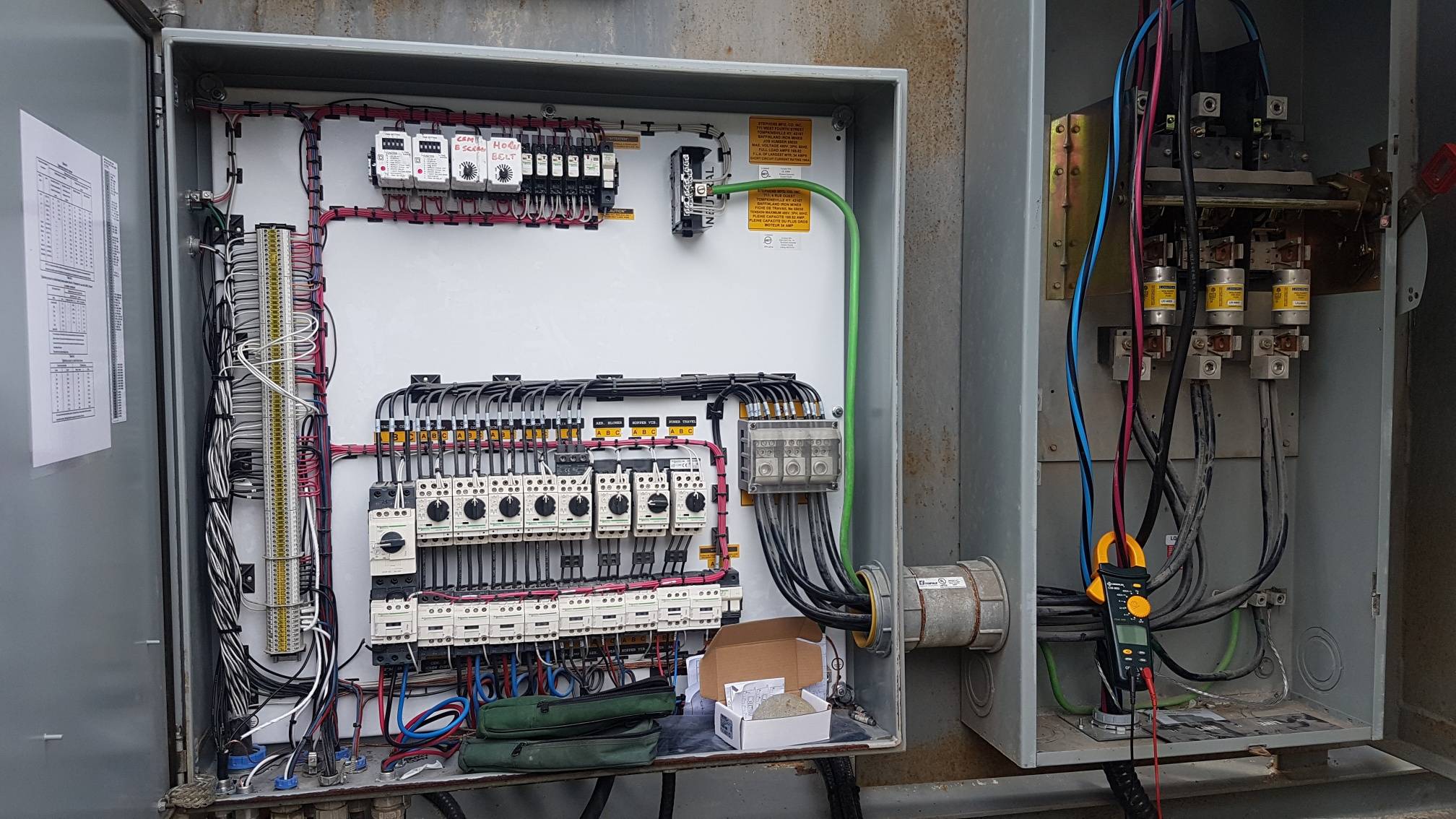

Optimus Electric can handle any job. We have extensive and specialized experience in commercial and industrial installations. Our experience includes, but is not limited to, hospitals, large department stores, farms and farm equipment, packaging facilities and distribution centers, and diesel power & concrete plants, to name a few.

Our skills include working with IO/OP PLC systems, integrating add mix controls, power correction, and power filters to help your plant or facility run smoothly and efficiently.

If it takes electricity and you need it, Optimus can help provide it.

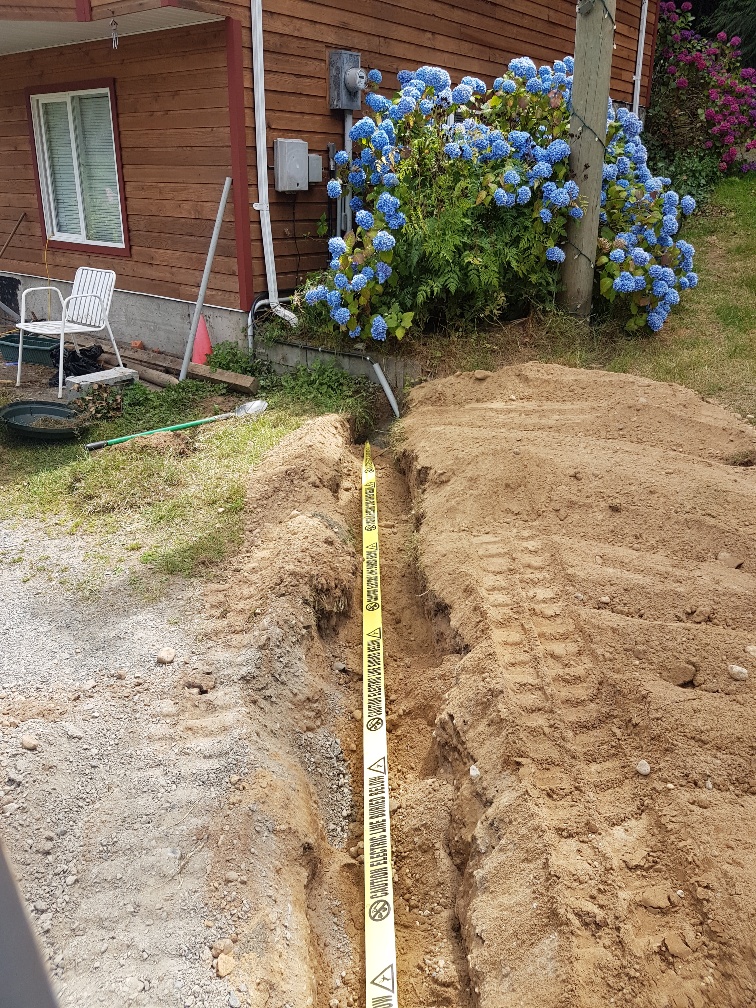

Excavation & Trenching

Learn More +

Let us do the digging while you save money!

Optimus Electric has its own digging and trenching equipment and machinery, so we don’t have to hire other people who will charge you more money. We are able to look after all of your underground wiring needs without adding in charges for equipment delivery and rental or sub-contractor rates and fees.

It's just another way that we are able to exceed your expectations and provide service that is above and beyond the ordinary.

Data Networks & Communication

Learn More +

Optimus also specializes in the design, installation, proofing, and maintenance of any size of structured cabling systems for all types of data, telecom, and voice networks.

We bring our expertise into every job we do, whether it is for your home network and entertainment or the critical care needs of a modern hospital, Optimus Electric can deliver what you need, where you need it.

Maintenance

Learn More +

The job is never really over when the installation is complete. Keeping your facility, or plant operating properly increases your safety and reduces your long range costs. That is why Optimus Electric offers many different options that can be customized to your specific needs.

An excellent example would be Thermal Imaging of all electrical equipment.

Internal heat is normal in electrical equipment. But over time, problems can develop that cause excessive heat and cause dangerous overloads and damaged or destroyed equipment. These reasons are varied but can be caused by contact problems, unbalanced loading, age cracks in insulation, worn and defective relays or terminal blocks and more.

A Thermal Maintenance program allows for prevention of excessive heat abnormalities in electrical equipment that is necessary to prevent otherwise unforeseen failures, unplanned power outages, possible injuries and their associated costs and grief and may possibly prevent a loss of production in a plant or manufacturing facility. We are now able to provide a fast, reliable, non contact and cost effective infrared thermographic inspection that is being widely used for detecting where and how both internal and external defects occur in equipment. The inspections are non-intrusive and do not interfere with the operation of the equipment. Both preventative and predictive can now be adopted for defect diagnosis and improved equipment safety and operation.

Ready to bring in the experts?

Photos of our Commercial and Residential Projects: